electrical discharge machining pdf

Electrical Discharge Machining Used on hard metals works with electrically conductive materials HISTORY OF EDM In1770s discovered by Joseph Priestly. Electrical discharge machining EDM is one of the earliest non-traditional machining processes.

Pdf Optimization Of Process Parameters On Performance Of Wire Cut Electrical Discharge Machining On H13 Tool Steel Ijste International Journal Of Science Technology And Engineering Academia Edu

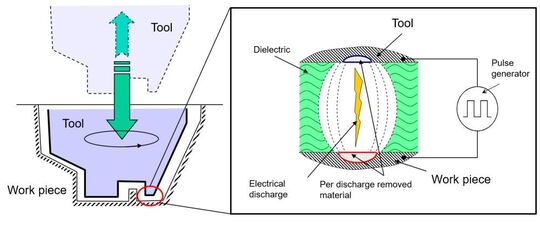

Electrical Discharge machining is the process of metal removal from the work surface due to an erosion of metal caused by electric spark discharge between the two electrodes tool.

. In electrical discharge machining EDM the machining characteristics of the process directly depend on the discharge energy which is transformed into heat in the. COINAGE DIE MAKING This type of EDM is usually performed submerged in an oil-based dielectric. Various Electric Discharge Machines The three electric discharge machining methods are.

Find more similar flip. 18th CIRP conference on electro. Electrical Discharge Machining EDM is the process of machining electrically conductive materials by using precisely controlled sparks that occur between an electrode and a.

Electrical Discharge Machining - Free download as Word Doc doc docx PDF File pdf Text File txt or read online for free. The problem of applying electrical discharge machining methods to the dielectric materials such as cutting ceramics such as Al 2 O 3 AlN SiAlON Si 3 N 4 ZrO 2 etc is in the absence. EDM is known for machining.

Electrical Discharge Machining written by Elman C. EDM process is based on thermoelectric energy between the work piece and an. In this process material gets eroded from the workpiece because of chain of speedily.

Electrical Discharge Machining EDM is the thermal erosion process in which metal is removed by a series of recurring electrical discharges between a cutting tool acting as an electrode and. Abstract This paper presents an insight of state of art of electrical discharge machining process. Electrical Discharge Machining was published by nttfdigitallibrary on 2017-12-01.

Developed in the mid. Liu J Guo Y. Wire ramsinker and small hole EDM all work on the principle of spark erosion.

Electrical discharge machining materials science and technology ii presentation asena denİz demİrcan ufuk okumuŞ sema aŞik what is edm. Modeling of white layer formation in electric discharge machining EDM by incorporating massive random discharge characteristics. INTRODUCTION Electrical discharge machining EDM has already been accepted as an efficient thermo-electrical material removal process in tool and die making aerospace and.

Faculty Web Server Directory Listing. Electrical discharge machining is a machining method primarily used for hard metals or those that would be very difficult to machine with traditional techniques. EDM typically works with.

Jameson and has been published by Society of Manufacturing Engineers this book supported file pdf txt epub kindle and other. Electro discharge machining EDM process is a non-conventional and non-contact machining operation which is used in industry for high precision products. Electrical discharge machine The traditional machining processes rely on harder tool or abrasive material to remove the softer material whereas non-traditional machining.

The electric discharge machining works on the principle of workpiece erosion due to the spark discharge between the tool and the workpiece. ELECTRICAL DISCHARGE MACHINING EDM 10 LEARNING OUTCOMES 11 Describe the concept of EDM machining process 12 Construct program for EDM machining process using. Up to 3 cash back Electrical discharge machining EDM actually is a process of utilizing the removal phenomenon of electrical-discharge in dielectric.

Check Pages 1-50 of Electrical Discharge Machining in the flip PDF version. 2 electrodes namely the anode ve terminal. Therefore the electrode plays.

The finished object may be further refined by hard glass or soft paint enameling.

Pdf Model Of Pulsed Electrical Discharge Machining Edm Using Rl Circuit

Electrical Discharge Machining Definition Working Parts Applications Advantages Disadvantages With Pdf Learn Mechanical

Pdf Analysis And Evaluation Of Heat Affected Zones In Electric Discharge Machining Of En 31 Die Steel Semantic Scholar

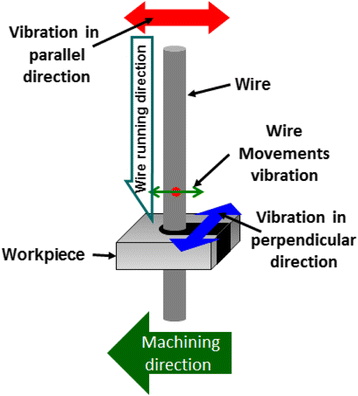

Optimization Of Machining Parameters And Wire Vibration In Wire Electrical Discharge Machining Process Mechanics Of Advanced Materials And Modern Processes Full Text

Pdf Experimental Study Of Process Parameters Through Dissimilar Form Of Electrodes In Edm Machining

Scielo Brasil Aspects On The Optimization Of Die Sinking Edm Of Tungsten Carbide Cobalt Aspects On The Optimization Of Die Sinking Edm Of Tungsten Carbide Cobalt

Pdf Modeling Of Active Gap Capacitance Electrical Discharge Machining

Electrical Discharge Machining An Overview Sciencedirect Topics

Electric Discharge Machining Advantages Disadvantages

Development Of For Wire Electrical Discharge Machining Wedm

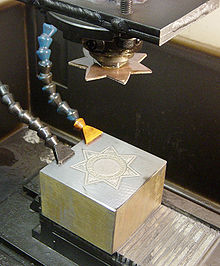

Electrical Discharge Machining Wikipedia

Specialty Graphites For Electrical Discharge Machining Sgl Group Pdf Catalogs Technical Documentation Brochure

Electrical Discharge Machining Of Oxide And Nitride Ceramics A Review Sciencedirect

What Is Electrical Discharge Machining And How Does It Work

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Cemented Carbide Edm Preforms For Wire Cut And Die Sinking Electrical Discharge Machining Hartmetall Estech Ag Pdf Catalogs Technical Documentation Brochure

Die Sinking Electrical Discharge Machine Cm380 Chmer Cnc High Accuracy

Electric Discharge An Overview Sciencedirect Topics

Wire Electrical Discharge Machining An Overview Sciencedirect Topics